3D printing technology has long been an attractive proposition for the Automotive Industry in the early stages of its Design Process.

As a result, additive manufacturing has been increasing in the Auto sector. According to the 2015 Wohlers report, 16.1% of the 3D Printing Market in 2015 was accounted for by the Automotive industry.

Recent improvements in additive manufacturing allow for newer designs, lower costs and are paving the way for new ways of designing and producing cars.

We can see this in action by looking at some of the current uses of 3D printing in the automotive manufacturing industry.

Audi & 3D printing

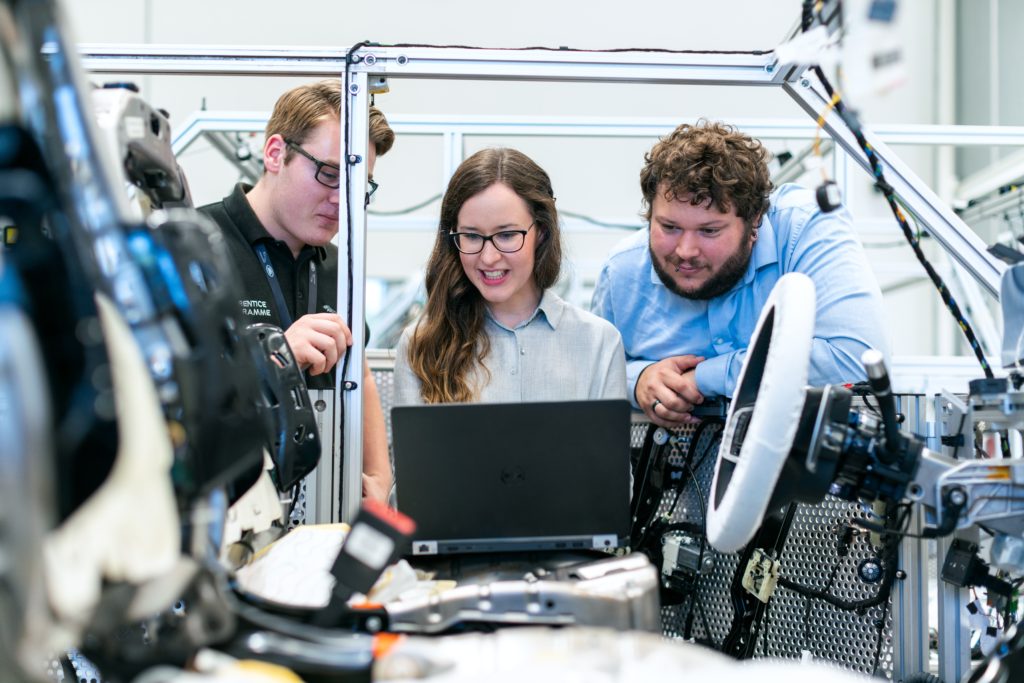

Audi, a German giant in the automotive industry, has long used 3D Printing. However, Audi launched a centre just for 3D Printing in Ingolstadt in 2017.

Audi is currently working with a 3D printing company called SLM solutions, specializing in metal 3D printing, to produce spare parts and prototypes.

Industrial 3D Printing has its advantages when compared to traditional manufacturing. 3D Printing allows highly complex parts to be designed in low volumes for an affordable price. Hence why 3D printing is perfect for a car company like Audi making one-off prototypes for testing.

Porsche & 3D printing

Not being able to purchase a spare part for an older car is a dilemma many motorists have had to face at some point. The reason companies no longer supply spare parts for older cars is because it is no longer cost-effective to produce such a small number of parts.

Porche, however, decided to try and solve this issue by taking advantage of 3D printings cost-effectiveness for low volume manufacturing.

Porche is currently using SLM 3dprinting for metal components and SLS 3d printing for plastic ones, which allows them to supply rare components for their older cars.

Rolls Royce & Additive manufacturing

Rolls Royce has been working closely with 3D printing to increase its production numbers. Each car that Rolls Royce makes is unique to its owner as Rolls Royce allows complete customization of their vehicles.

However, manufacturing cars in such a way is quite costly regarding time, so in a bid to reduce the production time of each vehicle, BMW (Rolls Royce’s Parent company) 3D printed 10,000 components for the Rolls Royce Phantom.

Hackrod & Custom 3D printed Cars.

In February 2018, American based startup Hackrod launched a Kickstarter to develop a platform for customizing cars and motorcycles. Hack rod smashed their initial $50,000 target by raising over $339,409.

The concept of Hackrod is to build a platform that caters for customers that want to design their cars digitally. The company plans to produce a range of sports cars; however, it doesn’t want to follow the traditional route of automotive manufacturing of having factories, equipment and staff, but instead wants to 3D print the majority of its car.