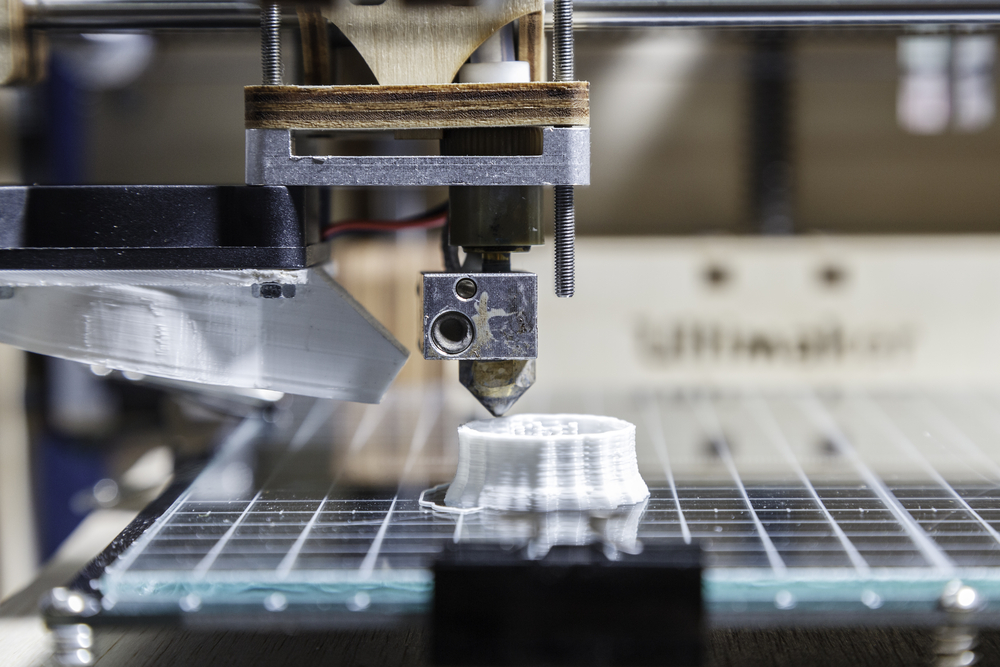

There are a wide range of different materials that can be used in 3D printing, both with traditional mechanical uses like plastics & metals and nontraditional organic or edible filaments that push the boundary of what’s possible with 3D printing. When it comes to personal printing, plastic is incredibly popular due to its availability, flexibility, and lower-end price point.

In many cases, you’ll have to decide between using ABS or PLA for your next project. But which one is right for you?

ABS vs PLA

Acrylonitrile Butadiene Styrene (ABS) and Polylactic Acid (PLA) are both types of plastic filament that are primarily used in FDM printing. In some cases, they may be interchangeable due to similarities in their cost, accuracy, and print speeds. However, there are some differences in their characteristics that can be the deciding factor in your choice.

If you’re looking for a material that produces a stronger, more resilient object, ABS’s higher heat resistance, flexural strength, and overall ability to withstand physical wear may render it the best option for you. It is also lighter, which can help in certain applications where weight matters like car parts. This makes it an effective prototyping material, but it may not produce the highest-quality aesthetic and may shrink or become brittle in colder temperatures.

Alternatively, PLA is often able to create finer details, sleeker exterior finishes, and sharper corners that make it a more aesthetically pleasing option that lends itself better to models where the physical and visual accuracy and appeal of the object are priority. However, these models may not be ideal for mechanical use, moving parts, high-temperature applications, or situations where it needs to stand up to wear or resist shattering.